Pelletizer / pelletizing recycling masine

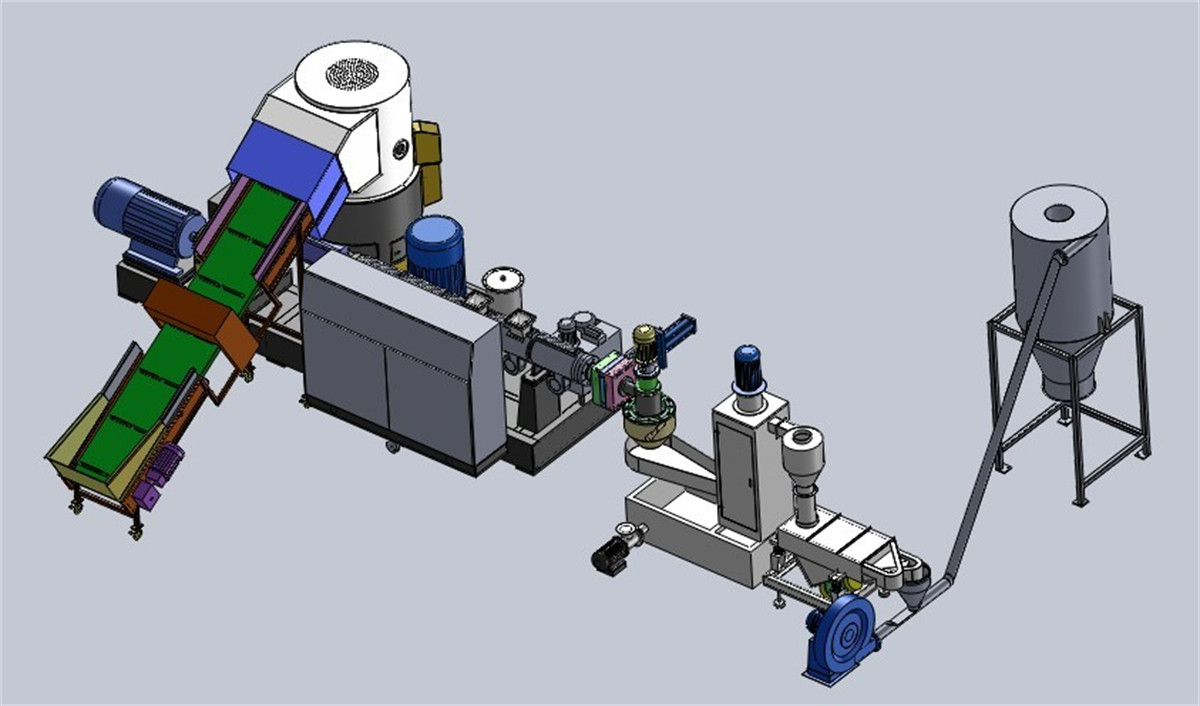

Proses flow

Screw feeder (OPSJONAL)→ Force feeder→1# Degassing screw extruder →1# Hydraulic filter exchanger→2# screw extruder →2# Hydraulic filter exchanger→ Mold head →Water ring cutting →Dewatering machine→ Luchtdroger Blowing system→ Storage hoper→ Ferpakking fan klear produkt.

Wy kinne produksjeline foar Granule dwaan fan ABS / PC / PP / PE / PVC / WPC neffens materiaal en útfier dy't wy ûnder ûntwerp hawwe:

PP PE ôffal plastic film recycle pelletizing masine line plastic film granulator

Flow chart fan PP / PE scraps pelletizing line

De prosesstream fan PP / PE-slooppelletisearjende line is as folgjend:

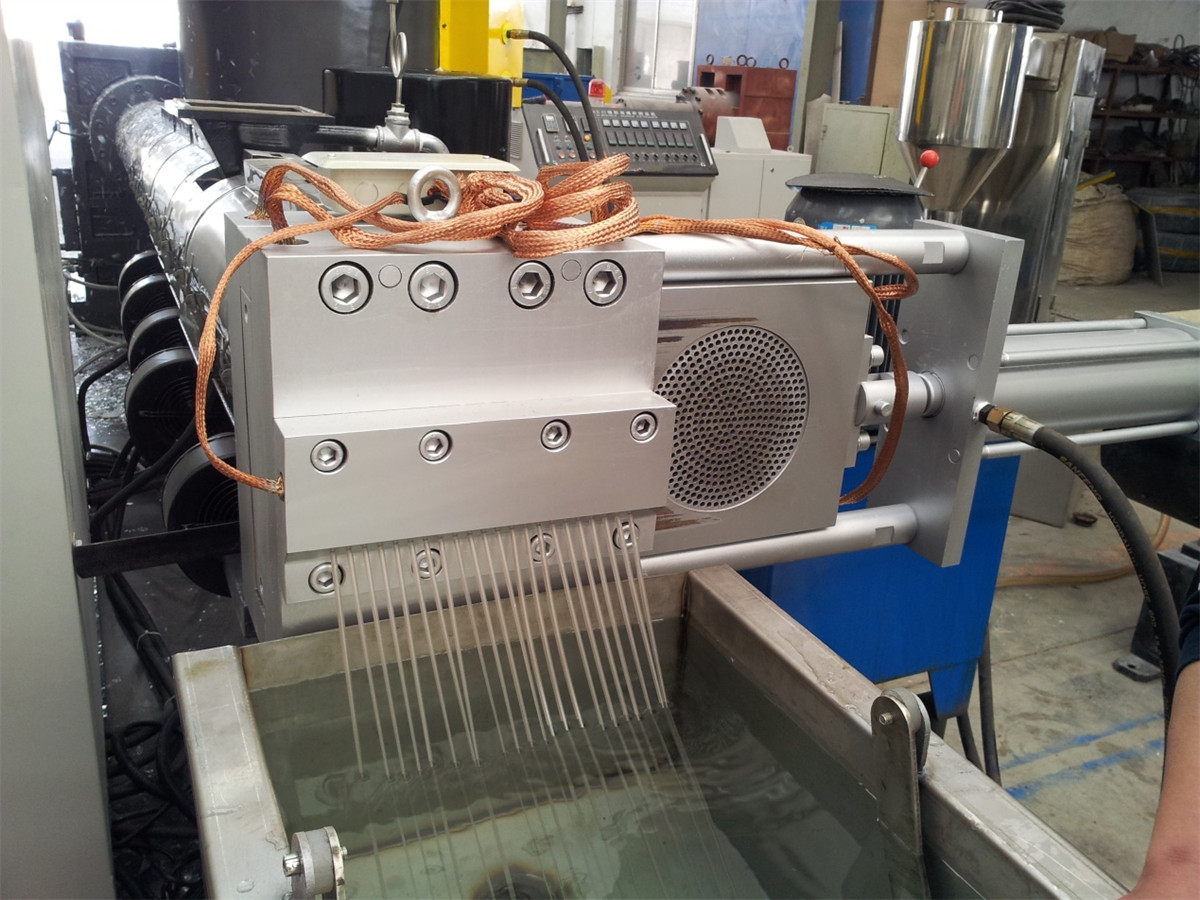

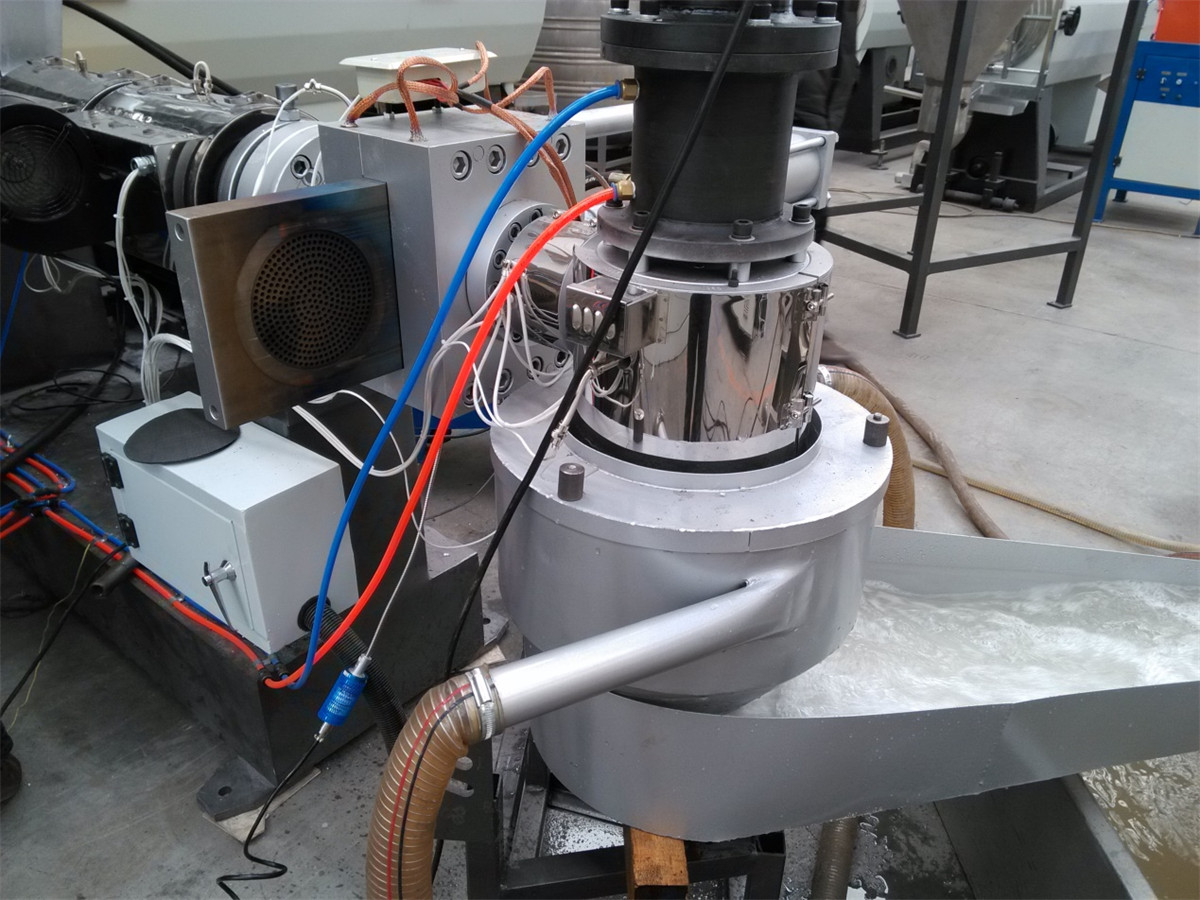

Screw feeder → Extruding systeem → Hege snelheid Net útwikseling systeem → wetter ring pelletizing masine → wetter trough dewatering masine triljende sieve lucht blower systeem → Storage

200kg / oere PE / PP scraps Pelletizing line

Produkt list

- 1 set plastic crusher

- 1 set lucht blower feeder

- 1 set schroef feeder

- 1 set side force feeder

- 1 set fan schroef feeding doseren masine

- 1 set SJ100/30 Extruding Machine

- 1 set fan hege snelheid Net útwikseling systeem

- 1 set wetterring pelletisearjende masine

- 1 set wetterbak

- 1 set fan dewater Machine

- 1 set trillende sieve

- 1 set fan lucht blower systeem

Oanfraach

Double-stage weromgewoane pelletizing produksje line is de ideale apparatuer foar plastic pelletizer, benammen foar PP, PE film ôffal, HDPE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS, XPS, stretch film Non-woven stoffen, woven bags, fêste materialen weromfûn, crushed materiaal recovery en granulation.De produksjeline hat de foardielen fan nij ûntwerp, ridlike struktuer, stabile operaasje, leech lûd, leech enerzjyferbrûk en hege útfier.